Introduction to Enterprise Resource Planning

Enterprise Resource Planning is the latest high end solution, information technology has lent to business application. The ERP solutions seek to streamline and integrate operation processes and information flows in the company to synergise the resources of an organisation namely men, material, money and machine through information. Initially implementation of an ERP package was possible only for very large Multi National Companies and Infrastructure Companies due to high cost involved. Today many companies in India have gone in for implementation of ERP and it is expected in the near future that 60% of the companies will be implementing one or the other ERP packages since this will become a must for gaining competitive advantage.

A D V E R T I S E M E N T

Most organizations across the world have realized that in a rapidly changing environment, it is impossible to create and maintain a custom designed software package which will cater to all their requirements and also be completely up-to-date. Realizing the requirement of user organizations some of the leading software companies have designed Enterprise Resource Planning software which will offer an integrated software solution to all the functions of an organisation.

It was introduced by research and analysis firm Gartner in 1990. ERP systems now attempt to cover all core functions of an enterprise, regardless of the organization's business or charter. These systems can now be found in non-manufacturing businesses, non-profit organizations and governments.

To be considered an ERP system, a software package must provide the function of at least two systems. For example, a software package that provides both payroll and accounting functions could technically be considered an ERP software package

Enterprise Resource Planning

Enterprise Resource Planning

Some organizations � typically those with sufficient in-house IT skills to integrate multiple software products � choose to implement only portions of an ERP system and develop an external interface to other ERP or stand-alone systems for their other application needs. For example, one may choose to use human resource management system from one vendor, and the financial systems from another, and perform the integration between the systems themselves.

This is common to retailers, where even a mid-sized retailer will have a discrete Point-of-Sale (POS) product and financials application, then a series of specialized applications to handle business requirements such as warehouse management, staff rostering, merchandising and logistics.

Ideally, ERP delivers a single database that contains all data for the software modules, which would include:

Manufacturing

Engineering, bills of material, scheduling, capacity, workflow management, quality control, cost management, manufacturing process, manufacturing projects, manufacturing flow

Supply chain management

Order to cash, inventory, order entry, purchasing, product configurator, supply chain planning, supplier scheduling, inspection of goods, claim processing, commission calculation

Financials

General ledger, cash management, accounts payable, accounts receivable, fixed assets

Project management

Costing, billing, time and expense, performance units, activity management

Human resources

Human resources, payroll, training, time and attendance, rostering, benefits

Customer relationship management

Sales and marketing, commissions, service, customer contact and call center support

Data warehouse and various self-service interfaces for customers, suppliers, and employees

Access control - user privilege as per authority levels for process execution

Customization - to meet the extension, addition, change in process flow

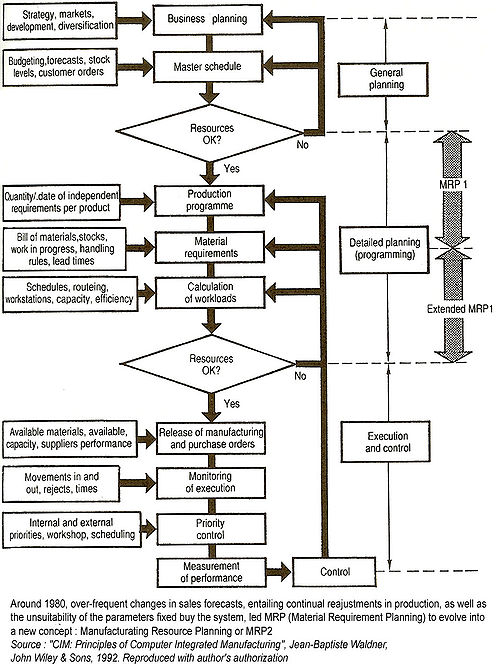

Enterprise resource planning is a term originally derived from manufacturing resource planning (MRP II) that followed material requirements planning (MRP). MRP evolved into ERP when "routings" became a major part of the software architecture and a company's capacity planning activity also became a part of the standard software activity. ERP systems typically handle the manufacturing, logistics, distribution, inventory, shipping, invoicing, and accounting for a company. ERP software can aid in the control of many business activities, including sales, marketing, delivery, billing, production, inventory management, quality management and human resource management.

ERP systems saw a large boost in sales in the 1990s as companies faced the Y2K problem in their legacy systems. Many companies took this opportunity to replace their legacy information systems with ERP systems. This rapid growth in sales was followed by a slump in 1999, at which time most companies had already implemented their Y2K solution.

ERPs are often incorrectly called back office systems indicating that customers and the general public are not directly involved. This is contrasted with front office systems like customer relationship management (CRM) systems that deal directly with the customers, or the eBusiness systems such as eCommerce, eGovernment, eTelecom, and eFinance, or supplier relationship management (SRM) systems.

ERPs are cross-functional and enterprise wide. All functional departments that are involved in operations or production are integrated in one system. In addition to manufacturing, warehousing, logistics, and information technology, this would include accounting, human resources, marketing and strategic management.

|